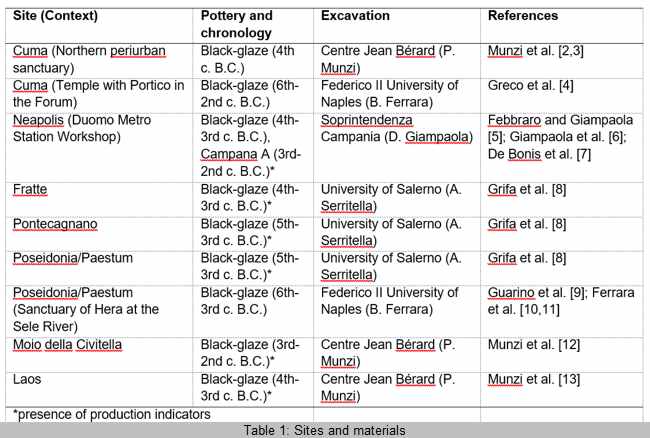

BG samples from Cuma were collected in the Northern periurban sanctuary and in the Temple with portico in the Forum (Table 1). From the workshop area of Neapolis at the Duomo metro station samples of the peculiar black-glaze pottery Campana A were investigated. This pottery was locally produced, as testified by the archaeological evidence and production indicators; in this site some older BG were also found and analysed (Table 1). Pottery and production indicators were analysed from the ancient cities of Fratte, Pontecagnano, and Poseidonia/Paestum; several samples also come from the sanctuary of Hera at the Sele river mouth (Table 1). Samples of BG and possible production indicators, represented by overfired samples, come from the fortification of Moio della Civitella (Table 1). BG and production indicators represented by wasters and clays hardened by fire in the kiln come from the settlement of Laos in the Calabria region (Table 1).

In order to investigate provenance and technology of pottery, samples were analysed via mineralogical-petrographic techniques: Polarised Light Microscopy (PLM), X-ray fluorescence (XRF), X-ray Powdered Diffraction (XRPD), Scanning Electron Microscope (SEM) with Energy Dispersive Spectroscopy (EDS). Provenance of pottery is investigated comparing its composition with the geological features in the surroundings areas of the discovery sites. For this reason, samples of clayey materials from the areas of interest were also analysed in order to find further evidence for the existence of local production [1].

Samples from Moio dell Civitella are less homogeneous and contain frequent fine siliciclastic inclusions and sporadic sandstone fragments, in some cases associated to rare clinopyroxene (Fig. 2h).

Most samples from Fratte and Pontecagnano, along with their production indicators, are characterised by a high concentration of CaO (Fig. 3b). Samples from Paestum are different. In particular, production indicators show affinity with a rather homogeneous group of samples from the Heraion. The other samples from the Heraion (light blue in the plots; Fig. 3b) have a scattered distribution and should represent imports, as expected in an open context such a Sanctuary. Several samples from Moio della Civitella also show a scattering; only some samples, characterised by a low CaO concentration, are more homogeneous. This group also comprises overfired pottery, probably indicating a specific production, but not necessarily local as they could also circulate as second choice pottery. It is worth to note that a sample found in Moio of Morel shape 1310 could be associated to the Campana A (Fig. 3b) and likely represents an import from Neapolis.

As for the Campana A, unfortunately, we have no evidence of local raw materials with a similar composition in the area of Neapolis. The composition of the Campana A also differs from that of the Ischia clay, which several authors claimed to be used for this production [7]. Lacking information on the presence of exploitable clay deposits in the area, a mixing of clay sources with different compositions could possibly be imagined to explain the peculiar chemical composition of the Campana A. As shown in De Bonis et al. [7], good results were obtained from a theoretical simulation (mass balance) of mixing between two raw materials present in the Bay of Naples: the calcareous Ischia clay and a non-calcareous weathered pyroclastics from the Sorrento Peninsula area, representing a volcanic-derived clay still used for making cooking pottery. Thus, a similar process of mixing could have be used for creating a standardised recipe for the Campana A production.

As far as coatings are concerned, they show some macroscopic differences. Coatings on Campana A are characterised by a metallic reflection, while the ones on black-glaze pottery can be either glossy or matt (Fig. 6a). In Figure 6b, the electron microscope microanalysis shows that the slips contain tiny iron particles and that their composition is enriched in iron (total iron as Fe2O3). In particular, coating on the Campana A is characterised by a double-layered slip, the inner one enriched in iron (Fig. 6c). This could be the reason of the metallic shine and birefringence observed in thin section.

In Figure 4b are shown the compositions of pottery and black coatings. They are characterised by a higher concentration of iron and aluminium oxides and are depleted in calcium oxide and silica. Comparing the composition of clay samples and their clay fractions separated experimentally and representing the levigated clays, the compositions of fine clays trend to that of coatings, thus suggesting that a strong refining of clays was probably performed for making the slips.

References

The geology of the area of Cuma and Neapolis is characterised by the presence of volcanic rocks, while marine sediments represented by clays also outcrop in the near Island of Ischia. In the area of Fratte and Pontecagnano carbonate and sedimentary rocks outcrop, including marine clays. The area of Paestum is mostly characterised by alluvial sediments of the Sele river plain, while the near mountain ranges are composed of carbonate and siliciclastic rocks, the latter also characterising the area of Moio della Civitella. The Laos area is mainly characterised by the presence of quartzarenite and clay deposits.

Petrographic analysis showed similar and very fine fabrics characterised by the presence of small inclusions. Most samples from Cuma found in both contexts are very similar and are composed of small quartz, feldspar and mica (Fig. 2a,b). A similar composition was noticed for black-glaze samples found in the workshop area of Neapolis, whereas the Campana A is characterised by a slightly coarser fabric with quartz, feldspar and volcanic inclusions (clinopyroxene and obsidian). It is interesting to notice that the black slips on Campana A are characterised by a double birefringent layer (Fig. 2c). Black-glaze from Pontecagnano and Fratte show a very similar composition, characterised by the presence of tiny crystals of quartz, alkali feldspar and mica (Fig. 2d, e). Samples from Paestum are characterised by more mica, coarser quartz and sporadic sandstone fragments (Fig. 2f), and they are similar to most of the samples found in the Heraion (Fig. 2g).

Samples from Laos are composed of tiny quartz and sporadic coarse fragments of quartzarenite, which characterise also production indicators, such as kiln wasters and a fired clay sample found in a kiln (Fig. 2i).

From a chemical point of view, BG from Cuma, belonging to both contexts, are very similar and are characterised by a high concentration of CaO (Fig. 3a). Also BG wares from the workshop of Neapolis are similar to the previous samples, thus suggesting that they might have been produced with the same raw material. Three samples from the Forum of Cuma of archaic age scatter in the plot (Fig. 3a). They were probably made with different raw materials or represent imports. The Campana A group is very homogeneous, showing a distinctive composition marked by a lower concentration of CaO and higher Zr and Nb (Fig. 3a), and it can be considered a reference group. It is worth to note that the three most recent samples found in the Forum of Cuma show a homogeneous composition to that of the Campana A (Fig. 3a), thus representing imports from Neapolis.

Black glaze and production indicators from Laos definitely differ from the other productions, especially considering trace elements (Fig. 3b).

In Figure 4 the compositional fields represent the supposed local BG groups that were compared with clayey materials collected in the surroundings of the investigated sites. Most samples belonging to both Cuma contexts show affinity with Ischia clays, which most probably represent the exploited raw materials (Fig. 4a). Samples from Fratte and Pontecagnano show a composition compatible with the local clays found in the area of Salerno and Montecorvino (Fig. 4a). These clays are exploited today for traditional productions of ceramics. Production indicators from Paestum and the local group of the Heraion are probably related to the alluvial clay collected in the surroundings of the Heraion (Fig. 4a). BG from Moio della Civitella and the overfired samples belonging to the low-CaO group allegedly represent a subregional production, as they can be associated to the clays from the area of Velia (Fig. 4a).

From a technological point of view, firing temperatures of the studied black-glaze wares mainly range from 850 to 1000 °C. This was inferred by the mineralogical transformations, in particular by newly formed calcium silicates in the calcareous pottery (Fig. 5a), and by the extensive vitrification of the ceramic body (Fig. 5b). The initial vitrification in the Campana A suggested slightly lower temperatures (~850 °C; Fig. 5c). In several samples both hematite and bivalent iron oxides (hercynite) are present (Fig. 5a), pointing out the occurrence of reducing stages of firing performed in order to provide the black colour of the coating.

In conclusion, this study provided important indications on the existence of local productions of black-glaze pottery in the investigated area, but also its circulation among different sites. Technological aspects of the black-glaze production were also addressed, especially regarding mix-design, firing dynamics and coating preparation.

However, this study also highlighted some problems in analysing and interpreting this pottery. Being a fine ware, distinctive inclusions are not easily identifiable at microscope, thus chemical analysis provided a good support for interpreting provenance by comparing composition of samples, production indicators and raw materials. Nevertheless, possible compositional change determined by preparation processes (i.e., levigation, mixing) should be always considered.

As in other archaeometric investigations, this study once again evidenced the utility to compare a significant number of samples, selected from different sites, through an interdisciplinary and multi-analytical approach in order to achieve satisfying results.

[1] A. De Bonis C. Grifa G. Cultrone P. De Vita A. Langella V. Morra, Raw Materials for Archaeological Pottery from the Campania Region of Italy: A Petrophysical Characterization. Geoarchaeology 28, 2013, 478-503.

[2] P. Munzi V. Guarino A. De Bonis C. Grifa A. Langella V. Morra, Le ceramiche ellenistiche del santuario periurbano settentrionale di Cuma. In: FACEM (version 06/12/2012), http://www.facem.at/project‐papers.php

[3] P. Munzi V. Guarino A. De Bonis V. Morra C. Grifa A. Langella, The Fourth Century Black-Glaze Ware from the Northern Periurban Sanctuary of Cumae, in: G. Greco, L. Cicala (Eds.), Archaeometry. Comparing experiences. Quaderni del Centro Studi Magna Grecia 19, Naus (Pozzuoli 2014) 69-87.

[4] G. Greco A. Tomeo B. Ferrara V. Guarino A. De Bonis V. Morra, Cumae, the Forum: typological and archaeometric analysis of some pottery classes from sondages inside the Temple with Portico, in: G. Greco L. Cicala (Eds.), Archaeometry. Comparing experiences. Quaderni del Centro Studi Magna Grecia 19, Naus (Pozzuoli 2014) 37-68.

[5] S. Febbraro D. Giampaola, Ceramiche comuni e vernici nere dal quartiere artigianale di Piazza Nicola Amore a Napoli, in: FACEM (version 06/12/2012), http://www.facem.at/project-papers.php.

[6] D. Giampaola S. Febbraro A. De Bonis V. Guarino V. Morra C. Grifa A. Langella, The pottery workshop area at Piazza Nicola Amore, Naples. Black-glaze and common ware production: Archaeology and archaeometry, in: G. Greco, L. Cicala (Eds.), Archaeometry. Comparing experiences. Quaderni del Centro Studi Magna Grecia 19, Naus (Pozzuoli 2014) 89110.

[7] A. De Bonis S. Febbraro C. Germinario D. Giampaola C. Grifa V. Guarino A. Langella V. Morra, Distinctive Volcanic Material for the Production of Campana A Ware: The Workshop Area of Neapolis at the Duomo Metro Station in Naples, Italy. Geoarchaeology 31, 2016, 437-466.

[8] C. Grifa C. Germinario A. Langella A. De Bonis V. Guarino V. Morra, Dati preliminari dagli studi archeometrici su materiali ceramici da Pontecagnano e confronti con Fratte e Paestum, in: A. Serritella (Ed.), Fingere ex argilla. Le produzioni ceramiche a vernice nera del golfo di Salerno, Proceedings of the conference (Salerno 1 marzo 2013), Ergasteria 5, Pandemos (Paestum 2017) 47-54.

[9] V. Guarino A. De Bonis V. Morra, Le analisi archeometriche, in: B. Ferrara (Ed.), Il santuario di Hera alla foce del Sele. La ceramica a vernice nera. Quaderni del Centro Studi Magna Grecia 15, Silaris 2, Naus (Pozzuoli 2012) 30-44.

[10] B. Ferrara V. Guarino A. De Bonis V. Morra C. Grifa A. Langella, The sanctuary of Hera at the mouth of the Sele River: archaeometric analyses for the reconstruction of black glaze ware production at Paestum, in: G. Greco, L. Cicala (Eds.), Archaeometry. Comparing experiences. Quaderni del Centro Studi Magna Grecia 19, Naus (Pozzuoli 2014) 165-189.

[11] B. Ferrara V. Guarino A. De Bonis V. Morra C. Grifa A. Langella, La ceramica a vernice nera del santuario di Hera alla foce del Sele: primi risultati delle analisi archeometriche, in: A. Serritella (Ed.), Fingere ex argilla. Le produzioni ceramiche a vernice nera del golfo di Salerno, Proceedings of the conference (Salerno 1 marzo 2013), Ergasteria 5, Pandemos (Paestum 2017) 55-70.

[12] P. Munzi A. De Bonis V. Guarino V. Morra C. Grifa A. Langella, La ceramica a vernice nera dell'insediamento di Moio della Civitella: problemi, metodi e primi risultati di una ricerca, in: A. Serritella (Ed.), Fingere ex argilla. Le produzioni ceramiche a vernice nera del golfo di Salerno, Proceedings of the conference (Salerno 1 marzo 2013), Ergasteria 5, Pandemos (Paestum 2017) 83-96.

[13] P. Munzi, Les fours de potiers et la production cιramique ΰ Laos (Calabre), in: J.P. Brun (Ed.), Artisanats antiques dItalie et de Gaule, Mιlanges offerts ΰ Maria Francesca Buonaiuto (Naples 2009) 265-283.

![]() © Alberto De Bonis, Chiara Germinario, Celestino Grifa, Vincenza Guarino, Alessio Langella, Vincenzo Morra, Bianca Ferrara, Priscilla Munzi, Antonia Serritella

© Alberto De Bonis, Chiara Germinario, Celestino Grifa, Vincenza Guarino, Alessio Langella, Vincenzo Morra, Bianca Ferrara, Priscilla Munzi, Antonia Serritella

e-mail: alberto.de.bonis@univie.ac.at

This article should be cited like this: A. De Bonis C. Germinario C. Grifa V. Guarino A. Langella V. Morra B. Ferrara P. Munzi A. Serritella, The black-glaze production in the Tyrrhenian coast of southern Italy: a review of the archaeometric data, Forum Archaeologiae 83/VI/2017 (http://farch.net).