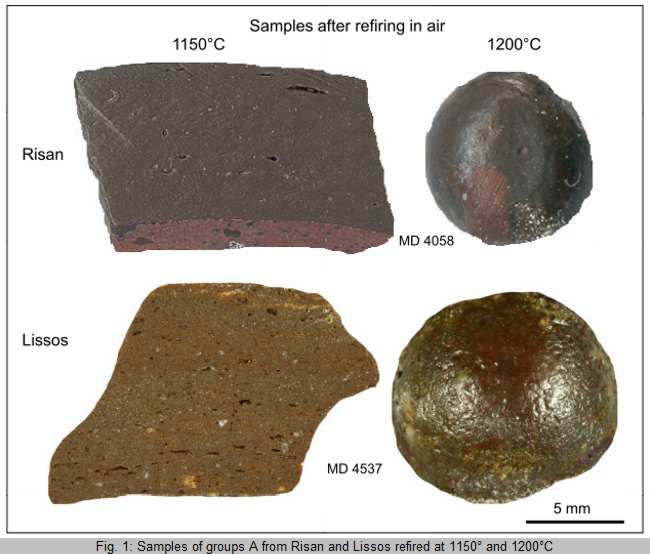

MGR-analysis of 193 samples of black-coated pottery found in Risan (Montenegro) and in Lissos (Albania) distinguished 21 major groups of different clays. These were combined to fewer chemical groups, which will be discussed later. The difference between group A from Risan (e.g. sample MD4058) and the chemically similar group A from Lissos (sample 4537) is obvious when fragments are refired at 1150° and at 1200°C (see example in Figure 1).

Refiring can also distinguish different techniques of creating black coatings, as was shown in the case of the Risan samples [2], where various changes occur in the colour of the black-coated surfaces when refired between 400° and 1100°C. Most samples lose their black surface colour already at 400°C, like sample MD4111 of group A (figure 2), which means that this is a non-vitrified slip. Therefore this layer will become oxidized when fired in excess of about 400°C. Real black gloss is represented by a sample of Gnathia-type pottery found in Pompeii (sample MD4211) which retains its black colour even above 900°C. The same is true for samples of Campana A and Attic ware. Their stable black colour is due to the formation of hercynite, magnetite and maghemite which are detected by XRD [3]. In sample MD4057 of group black disappears at 700°C. On the surface of this sample pine resin was detected [4].

80% of the samples of group A from Risan are coated with a non-vitrified black slip and are also distinguished from black-gloss-type sherds by a less hard surface which can be scratched by an iron nail. Measurement of open porosity and apparent density also revealed technological differences between the black-coated sherds of both groups A and B and Attic ware as well as Gnathia-type pottery.

To get comparable data when different labs are involved, the samples for analysis have to be treated in the same way. First, all outer layers including coating layers and surfaces liable to alteration affects [5] have to be removed mechanically and the samples, powdered in an agate mill avoiding any contamination, must be dried at 105°C and ignition losses at 900°C determined. While geologists normally analyse rock samples based on dried powders, for ceramics it is preferable to analyse the ignited powders for easier comparison of samples independent of losses on ignition (caused by different firing temperatures, organic material, alteration). Normalization of the sum of the oxides of the major elements to a constant 100% is another possibility when sulphur can be excluded. Intralab precision is essential and must be tested by repeating analyses (not measurements) at larger time intervals, and also the standard deviation of different samples taken from a single vessel (sampling error) should be tested [6].

To demonstrate long-term accuracy, the mean of 18 samples found at various sites analysed since 1996 and attributed to the sigillata manufacturing centre Lezoux are compared to the mean of 15 sherds found in Heidelberg, analysed in 1977 [8]. The data were also compared to those from other labs for the same reference group, also using WD-XRF (table 2).

Chemical analysis of black-coated pottery from Risan and Lissos revealed several compositional groups. Only few samples of Attic ware and Campana A were found in Risan. These were securely identified by comparison with reference groups available from our data bank. The bulk of the pottery is mainly distinguished by chromium and nickel contents. Figure 3 shows a bivariate diagram Cr vs. K2O of black coated pottery samples from Risan (red squares) and Lissos (blue triangles), and of published data from Phoinike (green circles) [9], Resnik, Cape Ploča (stars) and Vis (crosses) [10]. Analyses results of samples from the southern Adriatic coast in Italy (small brown circles) are added for comparison. Analyses results of clay samples from Durres (D) and from Risan (R) are marked as large yellow circles. In Risan as well as in Lissos two major groups were identified which we preliminary attributed to Albania (group A) and to Croatia or to S-Italy (group B). The same distinction of a high chromium group A and a minor low chromium group B could also be seen in the published chemical data of black-coated pottery from Phoinike (Albania) [11].

The groups A with high magnesium, chromium and nickel at Risan, Lissos and Phoinike are very similar in chemical composition and at first glance were interpreted as identical. As MGR-analysis shows for Risan and Lissos this is, however, not the case (example in figure 1). A closer look at the chemical data shows differences between groups A from Risan, Lissos and Phoinike, mainly in potassium and rubidium contents. A small shift of the overlapping groups can also be detected using multivariate analysis (cluster analysis, PCA or discriminant analysis), but the groups chemically cannot be differentiated securely. The inclusion of a stamped brick, a mould and a local clay sample suggested that group A from Phoinike represents local production. That the sherds of our group A from Risan (which by MGR analysis differs from group A from Lissos) have been made at Phoinike, however, is not very probable. This problem of securely distinguishing almost identical groups through chemical analysis alone is not unique [12]. From geological reasons all three groups A could have been produced in present day Albania and Italian imports are excluded. For groups B imports from Croatia or Italy are possible, however, the available chromium values for pottery produced in Croatia [13] are between about 250 and 450 ppm and thus clearly not similar to either groups A or B.

References

The determination of provenances using chemical analysis is based on the assumption that the compositional variation within one group is smaller than the differences between groups. Therefore, 1. the data must be precise and accurate (accurate for comparison with published data), 2. as many elements as possible must be determined (minimum fifteen), 3. for the determination of provenances secure reference groups must be available. The reference groups for all hypothesized workshop areas must be checked. Reference groups can be based on the following in order of decreasing significance:

To give an example of the necessary precision, five analyses of black-gloss pottery found north of the Alps [7] are shown in table 1. The analysis results indicate that the first four analyses very probably represent only two vessels, however, from the same provenance. Their difference to the analysis results of the fifth sample is significant in only a few elements (Ti, Al, and Cr), but this is sufficient to prove a different provenance. Of course, this conclusion is only possible because here a large database for comparison was available.

On the other hand, to exclude imports from the northern Adriatic to Montenegro and Albania is an easy case because of large chemical differences which also clearly separate various chemical groups of finds of black-gloss pottery at Aquileia, Altino, and Brescia (figure 4 [14]). Not included in the idiagram are the local group of vernice nera from Aquileia and the group of Centro-Padana ("poröses Fabrikat" from Magdalensberg) because these two groups are significantly distinguished either by having higher magnesium or higher chromium and nickel values than the four groups in the diagram.

Daszkiewicz 2014

M. Daszkiewicz, Ancient pottery in the laboratory – principles of archaeological investigations of provenance and technology, Novensia 25 (Warszawa 2014), 177-197.

Daszkiewicz and Baranowski 2010

M. Daszkiewicz, M. Baranowski, Provenance study of Late Classic and Hellenistic black-coated pottery from Risan (Montenegro), Novensia 21, 2010, 23-43.

Daszkiewicz et al. 2012

M. Daszkiewicz, G. Schneider, E. Bobryk, Wozu brauchen wir kombinierte Methoden für Keramikanalysen?, in: F. Schlütter, S. Greiff, M. Prange (Hrsg.), Archäometrie und Denkmalpflege 2012. Jahrestagung an der Eberhard Karls Universität Tübingen. Metalla Sonderheft 5 (Bochum 2012) 160-162.

Daszkiewicz et al. in press

M. Daszkiewicz, G. Schneider, M. Baranowski, D. Petrut, V. Rusu-Bolindeţ, N. Man, Moesian and Dacian sigillata – exploring regional patterns (a methodological approach using chemical analysis by WD-XRF and p-ED-XRF), Rei Cretariae Romanae Acta 45, in press.

Kysela et al. 2013

J. Kysela, M. Maggetti, G. Schneider, Black-gloss (“Campanian”) pottery in the Late La Tène central Europe – Preliminary archaeological and archaeometric studies, Archäolog. Korrespondenzblatt 43, 2013, 215-235.

Minguzzi et al. 2008

V. Minguzzi, M.C. Nannetti, E. Zentedeschi, Le ceramiche a vernice nera di Phoinike (Albania) – Sudio minero-geochimico a fini archeometrici, Rei Cretariae Romanae Acta 40, 2008, 55-62.

Olcese and Schneider 1999

G. Olcese, G. Schneider, Analisi di laboratorio sulle ceramiche provenienti da S. Giulia, in: G.P. Brogiolo (a cura di), S. Giulia di Brescia - gli scavi dal 1980 al 1992, Reperti preromani, romani e alto medievale, Firenze 1999, 221-230.

Šegvić et al. 2012

B. Šegvić, L. Šeŝelj, D. Slovenec, B. Lugović , R. Ferreiro Mählmann, Composition, technology of manufacture, and circulation of Hellenistic pottery from the eastern Adriatic: A case study of three archaeological sites along the Dalmatian coast, Croatia, Geoarchaeology 27, 2012, 63-87.

Šegvić et al. 2016

B. Šegvić, M. Ugarković, A. Süssenberger, R. Ferreiro Mählmann, A. Moscariello, Compositional properties and provenance of Hellenistic pottery from the necropolis of Issa with evidence on the cross-Adriatic and the Mediterranean-scale trade, Mediterranean Archaeology and Archaeometry 16, 2016, 23-52.

Schneider 1978

G. Schneider, Anwendung quantitativer Materialanalysen auf Herkunftsbestimmungen antiker Keramik, Berliner Beiträge zur Archäometrie 3, 1978, 63-122.

Schneider 2016

G. Schneider, Mineralogical and chemical alteration. Chap.11 in A. Hunt (ed.) The Oxford Handbook of Archaeological Ceramic Analysis (Oxford 2016).

[1] Daszkiewicz 2014.

[2] Daszkiewicz and Baranowski 2010.

[3] Micro-XRD was made by Ch. Berthold and K. Bente. Hercynite was also detected in 12 of 15 surface layers from Phoinike (Minguzzi et al. 2008, 57).

[4] Analysis by GC-MS was made by M. Ganeczko, B. Witkowski, and T. Gierczak.

[5] Daszkiewicz et al. 2012; Schneider 2016.

[6] Schneider 1978.

[7] Kysela et al. 2013.

[8] Schneider 1978.

[9] Minguzzi et al. 2008.

[10] Šegvić et al. 2012; Šegvić et al. 2016.

[11] Minguzzi et al. 2008.

[12] The pitfalls when using multivariate analysis are discussed in an example by Daszkiewicz et al., in press.

[13] Šegvić et al. 2012; Šegvić et al. 2016.

[14] Olcese and Schneider 1999; Kysela et al. 2013.

![]() © Malgorzata Daszkiewicz, Gerwulf Schneider, Patricia Kögler

© Malgorzata Daszkiewicz, Gerwulf Schneider, Patricia Kögler

e-mail: schnarch@zedat.fu-berlin.de

This article should be cited like this: M. Daszkiewicz - G. Schneider - P. Kögler, Analysis of black-coated pottery from Montenegro and Albania using MGR-analysis and WD-XRF, Forum Archaeologiae 83/VI/2017 (http://farch.net).